Engineering / SE

- Product Data Review

- Factory Layout

- Equipment Analysis

- Jig/Inspection Fixture/Cubing Design

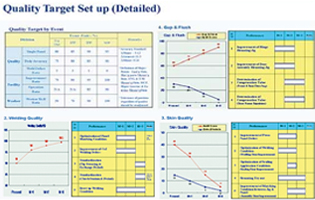

- Exterior Dimensional Management(DTS)

- Preparation for Quality Control

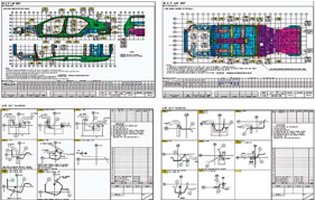

- Single & Assembly tolerance documents

- RPS, GD & T Documents

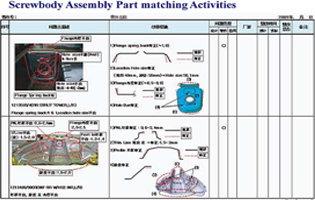

- Part matching Activities(S/Body ASSEMBLY)

- Assy Jig Management(Common hole T/O)

- Quality build up activities(BIW quality, Jig quality, Productivity)

- Quality activities report & Local engineer Training

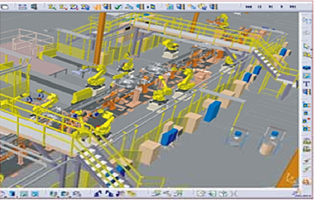

Simulation

- Driving simulation for Automatic Production Line

- Driving simulation for Robot & Affiliated Devices

Production items (Design and manufacture)

- Automation line equipment

- ROBOT peripheral facilities and devices

- Total inspection facilities, ASSY inspection facilities, single-piece inspection facilities, and fitting inspection facilities

- CO2 welding jigs and devices

Quality Development Program

-Regular improvement activities in each area of

management/design/manufacturing are carried out, and the improvement results

are applied to work to produce the best products. All executives and employees are making systematic efforts to realize cost reduction.

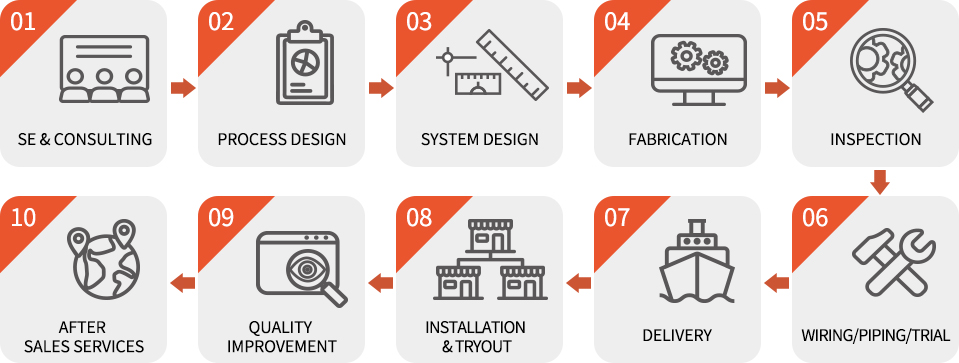

Production Process

1. SE and Consulting

2. Process planning

3. System Design

- ROBOT

Reviewing Concept / Welding point review / GUN setting / HANGER design / MODELING

- DESIGN

3D DESIGN / 3D MODELING / Final approval / Drawings Release

4. Machining and assembly

- BASE & LEVELING / UNIT assembly / GUN assembly / SHTL assembly / Function inspection

- BASE & FRAME face processing & HOLE processing / LOCATOR heat treatment / parts inspection

- Material preparation / installation (canning) / annealing treatment / inspection of canned materials

5. Inspection and Measurement

- CMM measurement

- FARO-ARM measurement

6. Wiring/Piping/Trial

- Piping route determination / V/V positioning / LINE MAIN piping / JIG internal piping / AIR supply test

- DUCT installation / LINE wiring / JIG wiring / I/O CHECK / Circuit input and operation test

7. Delivery

8. Installation and commissioning

9. Quality Development

10. After-sales service